Cage-guided control valve to reduce aerodynamic noise in compressible fluid service.

- Excellent low noise performance

- Porous structure combines squeezing, diffusion, and expansion to reduce pressure

- Structure resistant to vibration and wear

- Easy disassembly of valve body

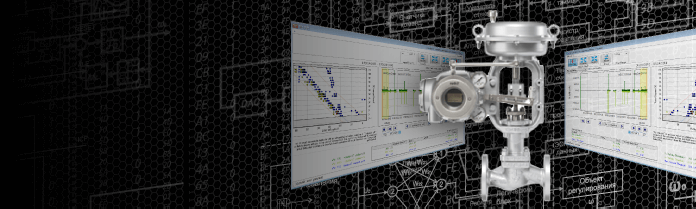

| Structural drawing | Image

| Image

|

|---|---|---|

| Valve type | Low-noise cage type double seated control valve | High pressure service low-noise cage type double seated control valve |

| Model No. | VDN_ _ _ | VDN_ _ _ |

| Size | 10", 12" | 1-1/2" to 12" |

| Pressure rating | ANSI/JPI 150 to 600 JIS10K to 40K | ANSI/JPI 900 to 2500 JIS63K |

| End connection | Flanged : RF, FF, RJ | Flanged : RF, FF, RJ Welded : SW, BW |

| Body material | Carbon steel Stainless steel | Carbon steel Stainless steel |

| Trim material | - | - |

| Temperature range | -195 to 600°C | 0 to 520°C |

| Leakage performance | - | 0.75% or less (percentage to rated Cv value) |

| Cv range | 600 to 860 | Class 1500 or less : 14 to 820 Class 2500 : 10 to 580 |

| Range ability | 25:1 | 30:1 |

| Application |

|

|

| Option | - | - |

A wide range of material specifications

Products can be provided by using different materials for valve stems - e.g., carbon steel is generally used with water, steam, and fuel oil; and high corrosion resistant stainless steel that is essential for controlling corrosive fluids.

Corresponding to service

The excellent anti-cavitation performance of these cage valves plays an essential role in controlling fluids at high temperatures and under high differential pressures. Optional specifications can be applied to reduce aerodynamic noise produced by steam and gas.

High control performance

High control performance is achieved by a combination of wide rangeability and a smart valve positioner.

The original internal valve structure adopted by azbil essentially eliminated the shortcomings of conventional double-seated control valves that suffered from reversal of fluid reaction force, thereby achieving stable control.