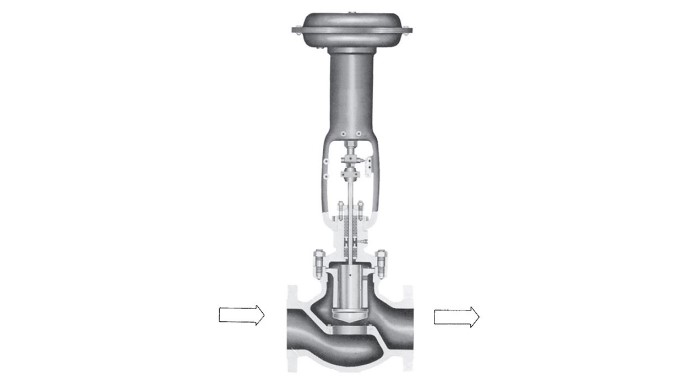

A single-seated control valve with sturdy construction and a valve structure suitable for slurry fluids.

- Flange rating: JIS10K to 30K, ANSI/JPI 150 to 600, corresponding to valve nominal sizes 5B, 10B, and 12B.

- Flange rating: JIS63K, ANSI/JPI 900 to 2500, corresponding to valve nominal sizes 4B, 5B, and 6B.

- The guide section has sufficient sliding area, and has a structure that is robust and easy to disassemble and inspect.

| Structural drawing | Image

| Image

|

|---|---|---|

| Valve type | Top guided single seated control valve | High-pressure service top guided single seated control valve |

| Model No. | VST_ _ _ | VST_ _ _ |

| Size | 5", 10", 12" | 4", 5", 6" |

| Pressure rating | ANSI/JPI 150 to 600 JIS10K to 30K | ANSI/JPI 900 to 2500 JIS63K |

| End connection | Flanged : RF, FF, RJ Welded : SW, BW | Flanged : RF, RJ Welded : SW, BW |

| Body material | Carbon steel Stainless steel | Carbon steel |

| Trim material | 440CSS 316SS, 316SS with CoCr-A 316LSS, 316LSS with CoCr-A | 440CSS SUS304 with CoCr-A |

| Temperature range | -101 to 520°C | 0 to 520°C |

| Leakage performance | Class IV, IV-S1, V, VI | Class IV |

| Cv range | 99 to 1440 | class 1500 or less : 56 to 315 class 2500 : 39 to 210 |

| Range ability | 30:1 | 30:1 |

| Application | General-use process for petrochemical and chemical plant | High temperature and high pressure steam of boiler and turbine unit for power plant and private power generation |

| Option | - | - |

A wide range of available materials

Products can be provided to meet a variety of body material specifications, such as: carbon steel, which is generally used with water, steam, and fuel oil; highly corrosion resistant stainless steel, which is essential for controlling corrosive fluids; and resin.

Response to severe service

For severe service such as high temperatures and high differential pressures, cage-type single-seat valves with excellent cavitation resistance are available.

Excellent seat leakage performance

Metal seat tight shutoff (class IV) and soft seat tight shutoff (class VI) are available.