Wetted parts of the body and trim of this control valve are high-performance ceramic for excellent corrosion resistance.

- Many applications for the control of acids, bases, and other corrosive fluids

- Uses a compact, high-output, multi-spring diaphragm motor

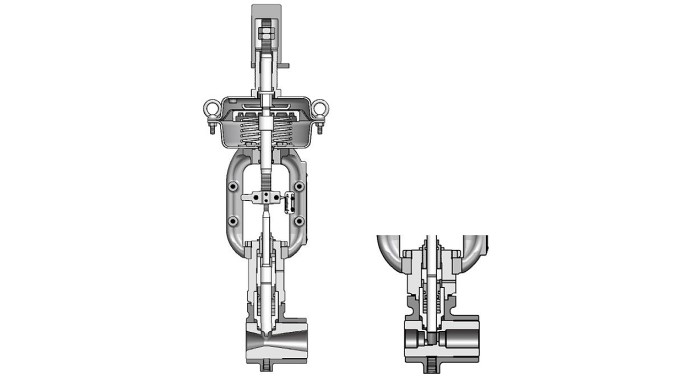

| Structural drawing | Image

| Image

|

|---|---|---|

| Valve type | Corrosion-resistant type small size ceramic control valve | Corrosion-/abrasion-resistant type ceramic control valve |

| Model No. | HMC_ _ _ | HIC_ _ _ |

| Size | 1" | 1" to 3" |

| Pressure rating | Max. pressure : 1960kPa | Max. pressure : 1960kPa |

| End connection | Wafer | Wafer |

| Body material | Body : 99% Alminum ceramic, silicon carbide ceramic Casing : ductile cast iron, stainless steel | Body : 99% Alminum ceramic, silicon carbide ceramic Casing : ductile cast iron, stainless steel |

| Trim material | 99% Alminum ceramic, silicon carbide ceramic | 99% Alminum ceramic, silicon carbide ceramic |

| Temperature range | 0 to 200°C | 0 to 200°C |

| Leakage performance | Less than 2.0% of maximum valve capacity | Less than 1.0 to 1.5% of maximum valve capacity |

| Cv range | 1 to 4 | 13 to 120 |

| Range ability | 30:1 | 30:1 |

| Application | Hard slurry service as flue-gas desulfurization, drainage, dissolving pulp slurry, and alumina refining unit | Hard slurry service as flue-gas desulfurization, drainage, dissolving pulp slurry, and alumina refining unit |

| Option | - | - |

Control valve with ceramic flow path