As a control valve manufacturer, we know how to achieve safe and stable operation and optimized maintenance through state-of-the-art technology

Our service visualizes valve health and detects warning signs that conventional methods would overlook. By reducing the time and effort needed for analysis and diagnosis, we help you focus on maintenance work. With our help, you can minimize the possibility of sudden problems and unplanned equipment shutdown caused by control valves.

Services

There are two main service options for the valve analysis and diagnosis service.

Dx Valve Cloud Service

Dx Valve Basic Service plus

The smart way to solve valve-related problems at production sites

Problem

- Failure is often unexpected because you can’t see the conditions inside the valve.

- I want to know if a problem is developing!

Solution

Early detection of problems

Using Azbil’s Diagnosis Service enables you to catch signs of abnormality before the process is affected.

Problem

- With time-based maintenance (TBM), valves that are in poor shape may be missed.

- But is condition-based maintenance (CBM) really feasible?

Solution

Optimize the selection of valves for periodic repair

If you know about valve deterioration in advance, you can overhaul valves that would not normally be selected for TBM, preventing future problems.

Problem

- Thanks to HART communication I have data on valve motion, but judging valve health is still quite difficult because I’m not a specialist.

Solution

Freedom to focus on critical work

Our full-time engineers analyze the data, diagnose valve health, and submit reports to you based on valve operating data, fluid and valve type, and the conditions of use. This frees you to focus on the work you need to do.

Problem

- Since we put so much time and effort into pre-startup inspections after periodic repair, starting up the equipment seems to take forever.

Solution

Streamline post-maintenance testing

We streamline various labor-intensive tests after periodic maintenance, so your equipment is back up and running quickly.

Highly reliable service, applying a valve manufacturer’s wealth of experience

We do the work of analyzing and diagnosing valve health for you,

in support of optimal valve maintenance planning.

By reducing the time and effort needed to use diagnostic tools, analyze the data, and make diagnoses, we free you to focus on maintenance work and help you to streamline work the smart way.

Diagnosed cases

Utilizing the Valve Diagnostics Service, you receive diagnoses of various phenomena so that you can prevent trouble.

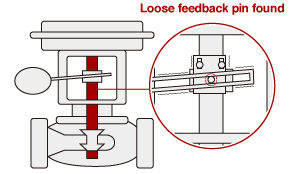

Device abnormality found

Something abnormal was detected in a loop that seemed OK according to the control results, and a potential problem was prevented.

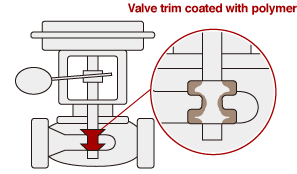

Valve clogging found

A problem was found in a valve that may have been excluded from TBM, improving the selection of valves to repair.

Customers and results

We are making an increasing number of diagnoses for many types of valves at a wide range of plants.

Daikin Industries, Ltd., Kashima Plant

The Daikin Industries Kashima Plant, which produces fluorochemical products for a industry, has recently focused on effective maintenance of control valves. The failure of a control valve has a greater impact on production than the failure of other instrumentation equipment used in plant operations, and control valves require large repair costs even in the course of regular maintenance. By switching from periodic maintenance to condition-based maintenance of these valves, the Kashima plant has significantly reduced maintenance costs and has established a system for quick handling of minor malfunctions and warning signs of future problems.

Ibaraki Plant of Mitsubishi Chemical Corporation

Monitoring of valve conditions using cloud services supports the safe operation of large-scale petrochemical plants.

NS Styrene Monomer Co Ltd Oita Works

With styrene monomer as its main product, NS Styrene Monomer Co., Ltd. (NSSM) meets a wide range of industrial needs. After repeated valve failures, the company’s Oita Works plant is now introducing smart valve positioners. The plant is also using a system to improve the monitoring of valve status. In this way, by providing a mechanism to track valve failure trends, a high level of plant operation stability is being achieved.

Inquiries