For digital transformation of the plant

Excellent environmental resistance and robustness

Dramatic improvement of control valve maintainability

Azbil’s advanced technology improves maintenance efficiency and reduces plant operation costs

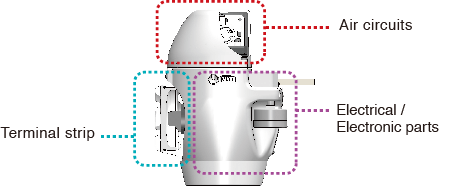

Unique separation of electrical and air circuits achieves high reliability in the field. In addition, the latest control valve diagnostic algorithms and communication technology contribute to stable and safe operation of the plant.

Unparalleled environmental resistance, robustness, and vibration resistance

Long-term continuous operation is possible even in corrosive gas environments, explosive atmospheres, seaside areas with a risk of salt damage, and other severe environments. Azbil’s smart valve positioners are highly reliable.

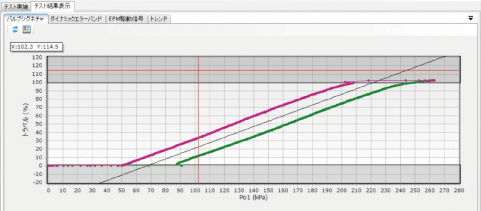

Advanced control valve diagnosis

With a pressure sensor mounted, abnormalities and control valve deterioration can be diagnosed. In addition, our unique online diagnostic algorithms are a great help in realizing condition-based maintenance and predictive maintenance.

Easy adjustment and changing of settings from anywhere, anytime

With the latest communication technology and man-machine interface technology, users can adjust or set up the positioner where and when they need it.

Advanced system integration

Positioners are compliant with the latest communication standards and are interoperable with related software groups, providing solutions such as early detection of control valves abnormalities, enhanced monitoring of critical control valves, and streamlined control valve inspection work.

- HART®

- FOUNDATION fieldbus

- FDT(Field Device Tool)

Smart ESD devices with SIL2 or SIL3 certification

The 700 series of smart ESD devices complies with IEC 61508 and has SIL3-Capable certification.

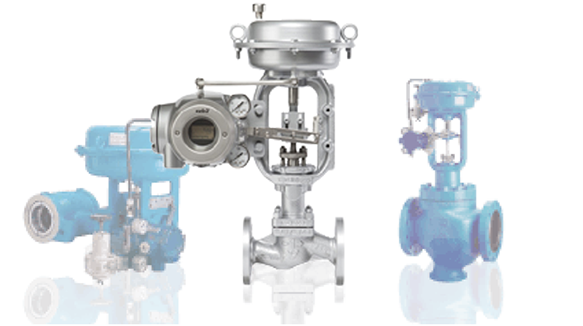

A wide variety of smart valve positioners

We have the right products for your needs, allowing you to select the best products for your plant’s varied requirements.

Whole-plant optimization with Azbil’s innovative automation technology

Control valves with over 80 years of proven reliability. For further streamlining of maintenance and reduction of plant operation costs, Azbil developed the PLUG-IN Valstaff control valve maintenance support system.

With Azbil’s control valves and systems, various control valve tests can be automated, significantly minimizing inspection work load and achieving an innovative process automation environment.

Control valve maintenance support system

- Prevention of unexpected problems and unplanned operation downtime

- Dramatic reduction in loop testing time