This angle control valve uses labyrinth trim to control cavitation around the seat.

- Use for blowdown control of saturated water where it is difficult to maintain shutoff performance due to high temperature and differential pressure

- Actuator uses a compact, high-output, multi-spring diaphragm motor with a simple mechanism.

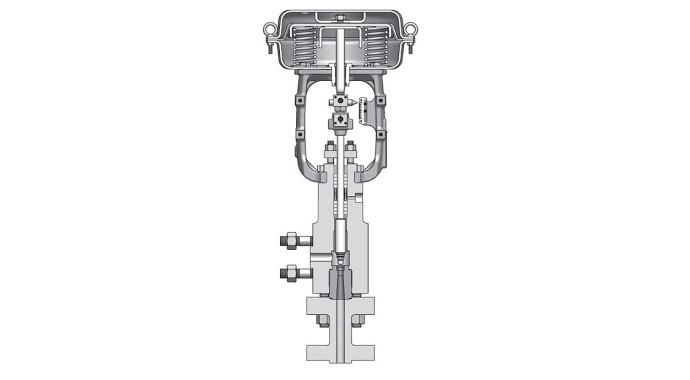

| Structural drawing | Image

|

|---|---|

| Valve type | Labyrinth trim angle control valve |

| Model No. | HAL_ _ _ |

| Size | 3/4" to 1-1/2" |

| Pressure rating | ANSI/JPI 900 to 2500 |

| End connection | Flanged : RF, RJ |

| Body material | Forged carbon steel Stainless steel |

| Trim material | 440CSS |

| Temperature range | 0 to 425°C |

| Leakage performance | Class IV |

| Cv range | 0.33 to 9 |

| Range ability | 30:1 (option 50:1) |

| Application | Labyrinth trim structure |

| Option | Bellow seal bonnet, steam jacket |

Angle valves are structured so that the center lines of the entrance and exit of the fluid intersect perpendicularly. In general, the horizontal line is the entrance and the vertical line is the exit.

This structure allows the fluids commonly known as slurry (i.e. viscous fluids and fluids including solid bodies) to pass more easily through the valve, making it suitable for controlling them. Additionally, it prevents the valve from being damaged due to fluid cavitation and flashing, making it suitable for fluids with these conditions.

This valve type is mainly adopted to solve problems that are difficult to address with general-purpose valves. Therefore, we can apply various materials (e.g., ceramic and cemented carbide) to the trim parts and its peripheral parts in order to handle special needs.