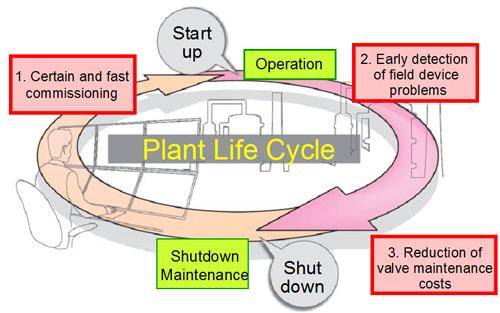

Azbil's HART/Fieldbus Solutions help to improve maintenance performance for field devices at 3 points in the plant life cycle.

1. Certain and fast commissioning

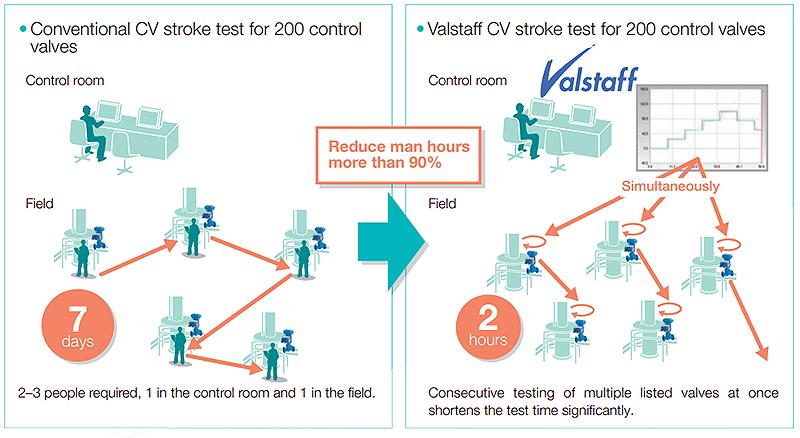

Dramatically improves the efficiency of continuity, loop, valve, interlock, and sequence checks before startup, helping to reduce the time required for routine maintenance.

Loop check work before plant startup is very important, and is generally carried out over several days with many people on site and one person in the control room.

By using InnovativeField Organizer before plant startup, efficiency can be dramatically improved for tasks such as device alive checks, loop checks, control valve testing, DCS sequence program testing, and DCS interlock program testing.

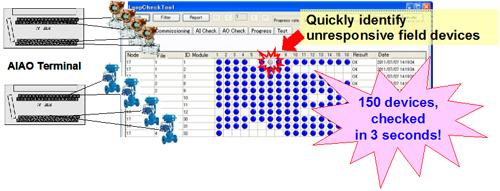

Alive check of multiple field devices can be done in seconds.

Dramatically improve work efficiency for loop checks

2. Early detection of field device problems

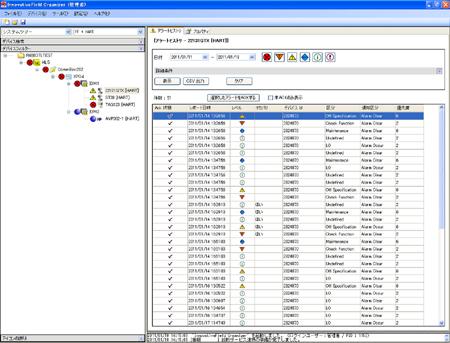

a. Continuous device monitoring

InnovativeField Organizer monitors device status 24 hours a day, 365 days a year. A device tree (like Windows Explorer) shows a list of field devices connected to InnovativeField Organizer, along with the current device status. If there is a problem, the device status is shown by symbols that are compliant with NAMUR NE 107.

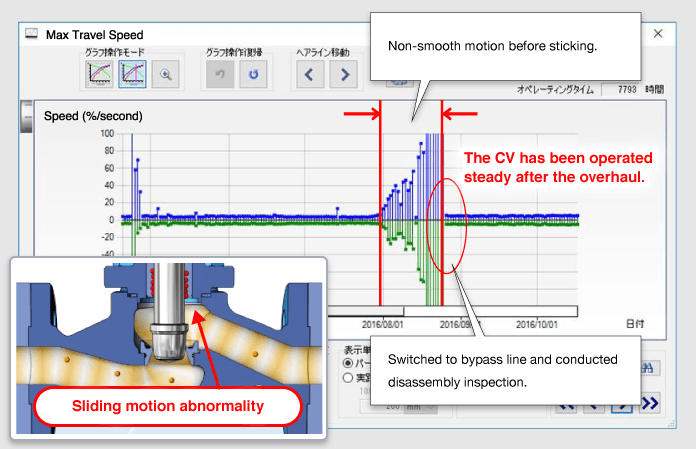

b. Online CV diagnostics while plant is in operation

Control valve abnormalities may lead to plant shutdown. Online CV diagnostics by PLUG-IN Valstaff support early detection of abnormalities by showing the CV's condition numerically and graphically.

3. Reduction of valve maintenance costs

Based on diagnostic data recorded during operation, a list of control valve candidates for overhaul inspection is created, contributing to the optimization of the overhaul.

The following pie chart shows the results from CV disassembly inspections at Azbil service shops. The chart shows that roughly 60% of CVs were judged to be normal and returned to service after cleaning. Valve maintenance tends to be overkill.

CV maintenance costs should be reduced by determining which valves require disassembly inspection based on their degree of deterioration.

Inquiries