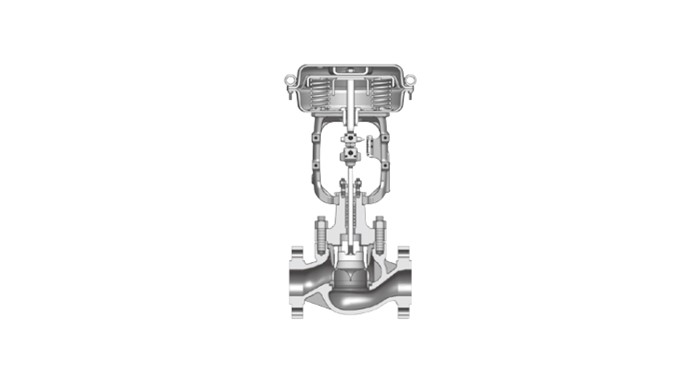

Cage-guided control valve to meet the needs of a wide range of applications.

- Large valve capacity with low pressure loss and highly accurate flow characteristics

- Main body structure with stabilizer for regulating fluid turbulence around cage

- Certified as SIL3-capable by exida Corporation

| Structural drawing | Image

|

|---|---|

| Valve type | Pressure-balanced cage type control Valve |

| Model No. | HCB_ _ _ |

| Size | 1-1/2" to 8" |

| Pressure rating | ANSI/JPI 150 to 600 JIS10K to 40K |

| End connection | Flanged : RF, FF, RJ Welded : SW, BW |

| Body material | Carbon steel Stainless steel |

| Trim material | SCS24 SCS14A with CoCr-A or Atomloy treatment SCS16A, SCS16A with CoCr-A |

| Temperature range | −196 to 566°C |

| Leakage performance | Class II, III, VI |

| Cv range | 36 to 850 |

| Range ability | 50:1 (option 75:1) |

| Application | General-use process for petrochemical and chemical plant |

| Option | Low emission gland packing Bellow seal bonnet |

A wide range of material specifications

Products can be provided by using different materials for valve stems - e.g., carbon steel is generally used with water, steam, and fuel oil; and high corrosion resistant stainless steel that is essential for controlling corrosive fluids.

Corresponding to service

The excellent anti-cavitation performance of these cage valves plays an essential role in controlling fluids at high temperatures and under high differential pressures. Optional specifications can be applied to reduce aerodynamic noise produced by steam and gas.

Excellent seat leakage performance

Metal sheet tight shut (class II, III) and soft sheet tight shut (class VI) are available.

Excellent external leakage prevention performance

A bellows seal can be added to valve stems. Increasingly sought-after specifications for gland packings can be applied to comply with fugitive emission regulations of volatile organic compounds.

High control performance

High control performance is achieved by a combination of wide rangeability and a smart valve positioner.

The original internal valve structure adopted by azbil essentially eliminated the shortcomings of conventional double-seated control valves that suffered from reversal of fluid reaction force, thereby achieving stable control.