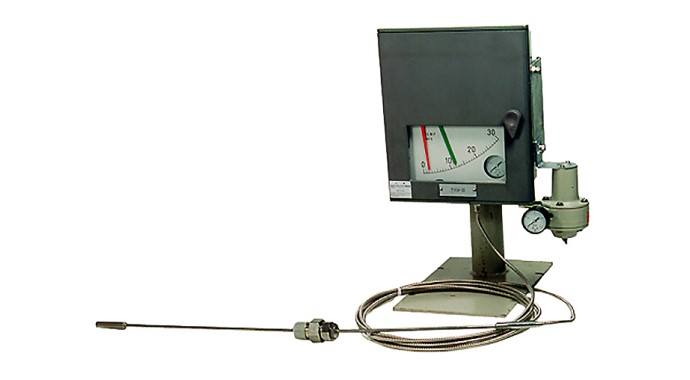

Model KFDB indicates and controls process variables by converting a change in the differential pressure into mechanical displacement of a torque tube or a torque arm.

- A wide variety of measuring elements and control mechanisms to meet various application needs

- A pneumatic circuit board and sturdy heat-resistant and weather-proof case greatly improve durability and reliability

- The pneumatic circuit board system allows the user to readily add or eliminate control mechanisms and units for flexible modification of functions.

Field mounted indicating controllers consist of two major parts which are found in all models. These are the process variable measurement unit and the indicating controller unit. The controllers measure and adjust basic process variables for temperature, pressure, flow rate, liquid level, and can also handle pneumatic pressure signals.

The entire series features superb functional design with consideration for cost and operability. A full lineup of indicating controllers, indicating transmitters, and indicating transmitting controllers is available for implementation of cost-effective instrumentation that meets a diverse range of functional requirements.

High reliability

We designed this series for both easy operation and improved reliability. Pneumatic piping circuit is replaced by a pneumatic circuit board to ensure functional reliability, a twin bellows is used for long-term stability, and a metal case makes the unit resistant to heat, water, and weather.

Excellent vibration characteristics

< Pressure measurement >

All spiral elements are equipped with a balance weight to suppress PV indicator oscillation. The structure also prevents eccentricity in the central shaft by determining the angle of displacement from the element center.

Countermeasures against process pulsation

Spiral elements with a damping feature that makes them resistant to process pulsation are utilized. Since there is no constriction, there is no need to worry about the possibility of clogging.

Economy achieved by standardizing parts

Due to the use of the same measuring element that is used in our existing pneumatic transmitters, efficient use of standardized parts, and the use of options that can be freely added or deleted, the number of parts that must be stored for maintenance has been drastically cut, and economy, maintainability, and operability have been greatly enhanced.