Streamlined pre-start preparation helps to shorten periodic repair periods

Since the preparation before starting up a plant is critical, it used to require several days of work by specialists. But with InnovativeField Organizer and the control valve maintenance support system PLUG-IN Valstaff, our customers have been able to dramatically streamline inspections and testing in order to shorten the periodic maintenance period.

Streamlining loop checks Streamlining step response tests Streamlining interlock and sequence checking

Streamlining loop checks

Maximizing instrumentation maintenance efficiency, InnovativeField Organizer carries out tasks that used to be dependant on multiple field technicians.

1. Analog input loop checks(e.g., 3 loops, 100 pressure gauges)

Conventional method

3days

Field technicians feed simulated input using a communicator, and an operator checks the result.

InnovativeField Organizer-based method

2hours

Instead of field technicians,InnovativeField Organizer obtains and monitors a variety of measurements.

2. Analog output loop checks(e.g., 5 points, round trip, 85 control valves)

Conventional method

2days

Field technicians check the actual opening of control valves against DCS output, and an operator changes DCS output manually.

InnovativeField Organizer-based method

3hours

Instead of field technicians, InnovativeField Organizer checks the actual opening of control valves against the DCS output. If OPC communication can be used with the DCS, instead of the operator, InnovativeField Organizer automatically changes the DCS output.

3. Streamlining AO loop checks using Yokogawa PRM + PLUG-IN Valstaff

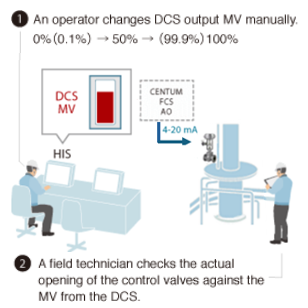

Conventional method

An operator changes the MV from the DCS manually, and field technicians check the actual opening of the control valves in response to the MV from the DCS.

New method

Reduce labor hours by 90% or more

Instead of the operator,PLUG-IN Valstaff automatically changes the output MV from the adjustment control block through Exaopc. Instead of field technicians,PLUG-IN Valstaff checks the actual opening of the control valves against the MV output from the DCS through PRM using HART communication.

This function is available in PLUG-IN Valstaff R51 and later

For details, please refer to our document “Users of Yokogawa Electric’s PRM can experience dramatically more efficient loop checking by PLUG-IN Valstaff before restarting the plant after regular maintenance, or when expanding or modifying equipment!”

Streamlining step response tests

PLUG-IN Valstaff performs step response tests to check whether valves open accurately and smoothly in response to commands. By plotting test results on graphs, PLUG-IN Valstaff makes it easier to assess performance and to identify deteriorating control valves and incompatibilities. Since tests can be run automatically on multiple control valves simultaneously, you can significantly reduce the work-hours needed for periodic repair and inspection.

Stroke test of 42 control valves

using a conventional method

1day

2–3 workers needed, 1 in the control room and 1 or more in the field.

Testing by PLUG-IN Valstaff

45min

Sequentially testing the listed valves, as many as 16 at a time, can save a lot of time.

Streamlining interlock and sequence checking

By using the InnovativeField Organizer simulated input tool for sequence testing or interlock testing, you can command simulated input in a batch from InnovativeField Organizer instead of sending simulated input at the production site or at the terminal board.

This tool eliminates the need for labor-intensive simulated input work, and helps make testing more efficient. In addition, there is a safety benefit. By eliminating wire disconnection work, it eliminates wiring errors that might occur when the instruments are reconnected.

Conventional method

Many workers are required for simulated input.

InnovativeField Organizer-based method

Batch sending of simulated signals frees you from highly labor-intensive work.

Significant reduction in labor hours

A must-see for those tasked with site improvement

- Utilization of a Valve Diagnosis Service to Enhance Safe Operation of Power Generation Facilities (case study)

- Dramatic Efficiency improvement in Valve Loop Checks During Regular Maintenance (case study)

- Optimize Maintenance Timing by Understanding the Tendency of Valves to Stick in the Acrylate Monomer Polymerization Process (case study)

Give some examples of how valve analysis and diagnosis prevented negative impact on plant operation.

How has valve diagnosis helped to promote DX at manufacturing sites?

Give an example of problem detection in a key valve of a boiler facility.

For a limited time, we disclose the latest trends and examples of valve analysis and diagnosis, which have undergone innovation through the use of information technology.

Inquiries