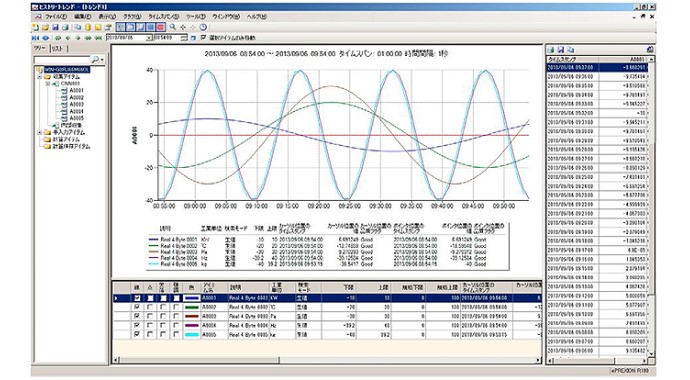

Collects and stores process and manufacturing data. Supports production management by visualizing operation information and with statistical analysis function.

ePREXION™ automatically collects process data or manufacturing data from various monitoring and control systems in plants and factories and stores it as long-term history data, providing an open environment for managing plant information. Data collected and stored by ePREXION can be easily used on networked PCs in various departments for an accurate understanding of operation and production status.

Keywords for digital transformation of the plant

ePREXION is connected to the control system via the industry-standard OPC communication ( OCP Classic and / or OPC UA ) , so it can be connected to a control system provided by an OPC server without using our interface. The product’s standard cycle for data collection from field devices is as short as 1 second, but a function that collects in milliseconds is available.

Data handling according to plant characteristics

- Periodic collection and storage

Collects tagged data from the control system periodically, appends a timestamp, and stores and manages the data as history data. Also, the server can be made redundant. - Event-based data collection and storage

Collects tagged data from the control system at user-defined timings and stores and manages it in a relational database. - Powerful calculation function

Flexible calculation using a simple language is available. If an error is found in the calculated result, the cause can be easily checked.

Use of open data

ePREXION history data can be easily used in trend and analysis tools, Excel, Access, and web browsers.

Easy to operate for both data users and system administrators

ePREXION offers very simple operation in all situations, from engineering to data usage and maintenance. Users only need to know how to use Windows.

Inquiries