This controller handles up to four loops with a top sampling cycle of 10 ms.

In addition, the separable display allows for flexible positioning.

The compact data storage and health index* functions make it useful in ways that conventional controllers cannot match.

- Accuracy: ±0.1 % FS

- Control channels: 4 max.

- Standard features include Ethernet and serial RS-485 communications (Modbus™)

- Smart loader package available

For use with semiconductor-manufacturing and food-processing equipment, among others, we have developed new controllers, model C7G/C7S, that maintains a consistent temperature within a loop. In spite of its compact frame, the C7G/C7S control as many as four systems simultaneously. For superior usability, the display unit is separable from the main unit and features a touch panel color LCD for ease of use and high visibility.

In addition, we have developed a health index function that uses sensing data and control signal (M.V.) amplitude to quantify changes in control loop behavior. This provides advance warning of equipment problems, allowing timely preventative maintenance.

Product Video

Preventive Maintenance of Manufacturing Equipment

Health index — Azbil’s proprietary parameter

Compact data storage (CDS)

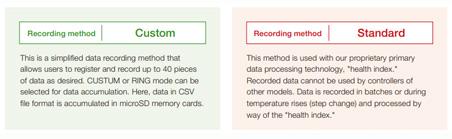

Compact data storage is Azbil's new technology for effective data recording. It can record necessary data at fixed intervals and also record just the required pieces of data, thus allowing controllers to achieve data processing and management at FA control layer.

Process diagnosis (Health index function)

Loop characteristics are quantified using process data for control. Loop soundness is monitored to detect status changes. Quantified data is provided for edge computing that in turn contributes to promotion of IoT services.

By comparing the maximum amount of process change in a transient response (delta PV_max) and the same value for the model installed in the controller (delta PVm_max) , the value of “Process gain (Kp) ÷ time constant (Tp)” is calculated as the health index (control loop quality). The health index is calculated while CDS is activated, and is then stored on the microSD memory card. (Depending on processing conditions, calculation may sometimes not be possible.)

How to use

The health index is an approximation of control loop condition. By storing data in batches and comparing it with initial values, equipment status changes can be detected before a failure occurs.

Detection sample of furnace oven

- Change the retio of air and gas

- Degradation of thermal insulation material

- Detection of furnace oven’s condition

- Detection of an exhaust condition

IoT Capabilities

Ethernet communication function

Compact data storage function

Excellent Usability

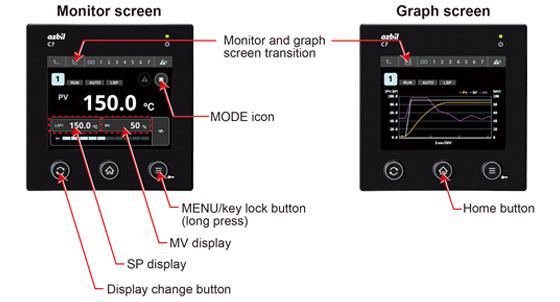

The QVGA LCD displays a greater amount of information than previous models

Intuitive operation on a touch panel

3.5-inch QVGA LCD and Resistive Touch Panel

3 Physical Keys for Easy-To-Understand Operation

Selectable home screen

One controller handles up to 4 loops. The C7G/C7S break the single-loop controller mold by allowing users to select the required number of loops. The loops that are displayed on the screen can also be changed through home screen settings.

Clarity at a glance-set for full name display of C7G/C7S alarms and settings

Parameter settings and gauge alarms can be displayed by name rather than by code number, reducing the need to refer to the manual during setup and alarm handling. Both English and 機械翻訳 are available, and can be seamlessly switched during operation.

Easily identify the cause of alarms

The hierarchical design of the alarm screen allows easy identification of the location and cause of generated alarms.

Graphs are helpful in trial-run adjustments

Control status can be conveniently checked on a graph while making trial-run adjustments.

Inquiries about control products