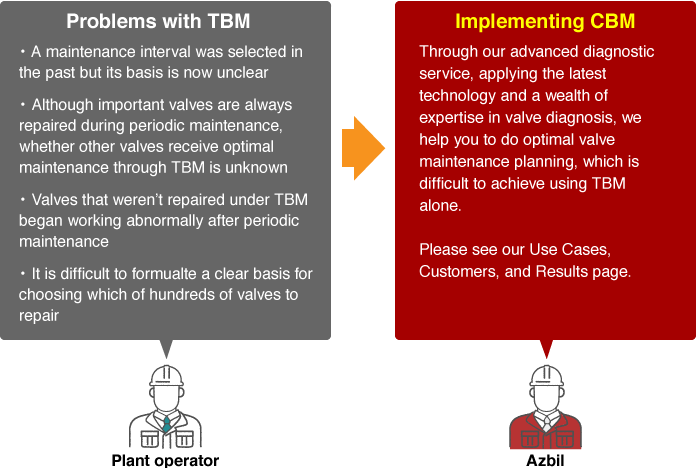

Switch to time-based maintenance (TBM) + condition-based maintenance (CBM) to optimize maintenance planning

Azbil, applying its wealth of expertise in valve diagnosis, analyzes operating data accumulated in the Valstaff system to diagnose the condition of control valves, helping you with maintenance planning.

Results of installation

Kawasaki Plant, Showa Denko K.K.

Smart industrial safety is being promoted by valve diagnosis using IoT. This contributes to stable plant operation and reduced maintenance costs.

A must-see for those tasked with site improvement

- Utilization of a Valve Diagnosis Service to Enhance Safe Operation of Power Generation Facilities (case study)

- Dramatic Efficiency Improvement in Valve Loop Checks During Regular Maintenance (case study)

- Optimize Maintenance Timing by Understanding the Tendency of Valves to Stick in the Acrylate Monomer Polymerization Process (case study)

Give some examples of how valve analysis and diagnosis prevented negative impact on plant operation.

How has valve diagnosis helped to promote DX at manufacturing sites?

Give an example of problem detection in a key valve of a boiler facility.

For a limited time, we disclose the latest trends and examples of valve analysis and diagnosis, which have undergone innovation through the use of information technology.

Inquiries