Without diagnosis, an unnoticed problem might suddenly escalate into trouble…

Trust Azbil’s Valve Diagnostics Service to help you implement condition-based maintenance (CBM).

A diagnosis helped to find a problem in a control valve that would not have been repaired under time-based maintenance (TBM)

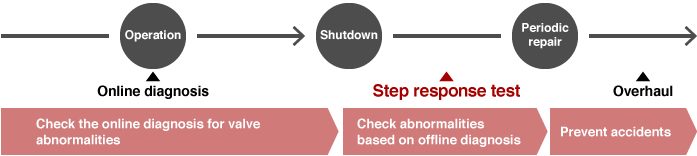

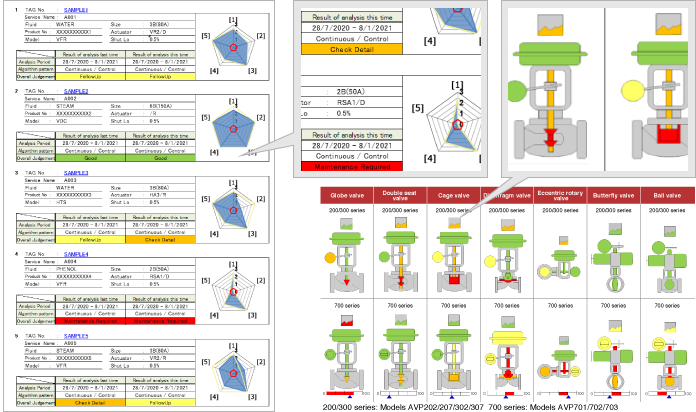

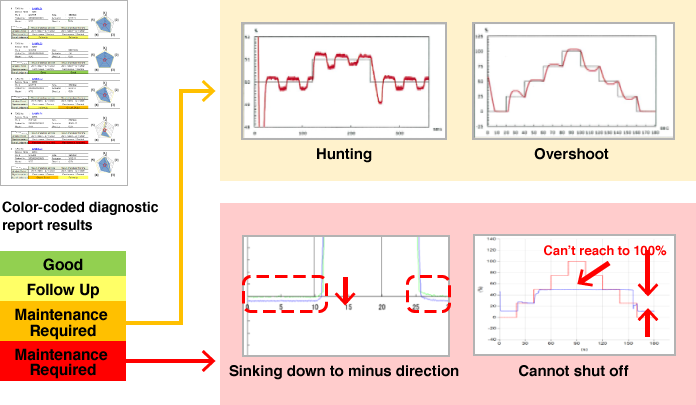

Online data-based diagnosis by our Valve Diagnostics Service during control valve operation detected an abnormality that would not have been repaired under TBM. The valve received Maintenance required and Check thoroughly evaluations.

A step response test revealed a problem that was unnoticed during operation

After shutdown, offline diagnosis revealed that there was something abnormal about the valve, so it was added to the overhaul inspection list.

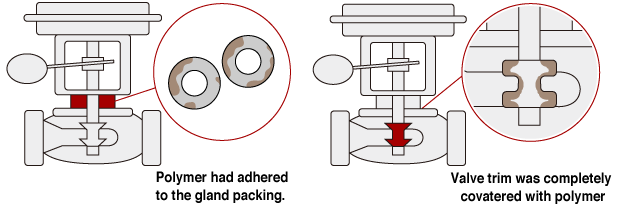

The overhaul inspection confirmed the diagnosis.

A must-see for those tasked with site improvement

- Utilization of a Valve Diagnosis Service to Enhance Safe Operation of Power Generation Facilities (case study)

- Dramatic Efficiency Improvement in Valve Loop Checks During Regular Maintenance (case study)

- Optimize Maintenance Timing by Understanding the Tendency of Valves to Stick in the Acrylate Monomer Polymerization Process (case study)

Give some examples of how valve analysis and diagnosis prevented negative impact on plant operation.

How has valve diagnosis helped to promote DX at manufacturing sites?

Give an example of problem detection in a key valve of a boiler facility.

For a limited time, we disclose the latest trends and examples of valve analysis and diagnosis, which have undergone innovation through the use of information technology.

Inquiries