Harmonas-DEO is a next-generation operation monitoring and control system that serves as the core of data-driven smart factories in the IoT era.

Harmonas-DEO is a next-generation operation monitoring and control system that serves as the nerve center for data-driven smart factories in the age of IoT. Through links to Azbil's proprietary online malfunction-prediction system, which makes use of AI (artificial intelligence), and to a system for utilizing monitoring and diagnostic data from individual smart devices, Harmonas-DEO provides data-based monitoring.

In addition, the enhanced operability and visibility of the human-machine interface (HMI) during operation monitoring promotes safer and more reliable operation.

Harmonas-DEO is Azbil's newest DCS compatible with the existing Harmonas™ and Industrial-DEO™.

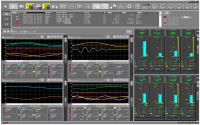

DCS HCI (human-centered interface)

Promote prompt situational awareness and swift comprehension and decision-making, and also provide guidance for correct operation: that is the concept behind the “human-centered interface” of Azbil's DCS.

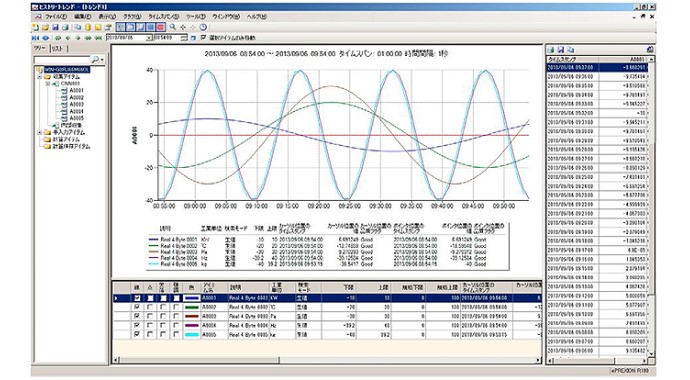

Window-Set Call-up (for standardized operation views)

Combinations of windows required for operation or monitoring can be registered and called up as sets. This eliminates differences between operators' views caused by differences in the screens that are displayed.

Multi-Information Window (preventing accidental oversights)

Windows are laid out in divided panes. Since information cannot be missed due to overlapping windows, this feature contributes to safe operation.

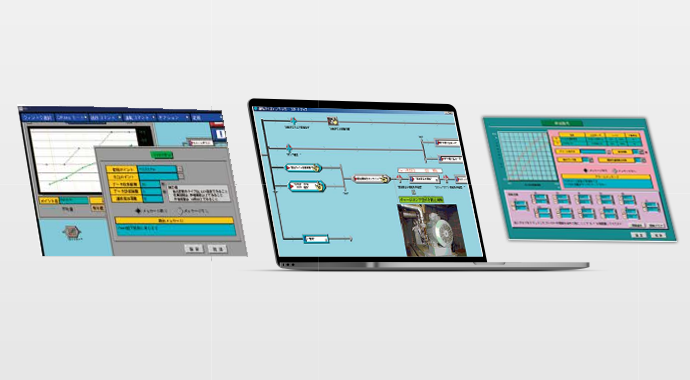

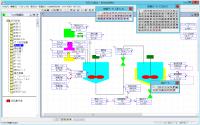

Easy Engineering Tool

The function design tool RTC makes design, maintenance, and modification of the control system easy. This tool provides extensive online help, graphics-based process control design, operation checks using smart simulation, and remote engineering (Real Time CoSEE*1).

Highly Reliable Triple-Redundant DOPC IV Controller

- Three CPUs (2-out-of-3 logic)

Three constantly synchronized CPUs perform calculations which are compared before outputting the results, resultling in improved reliability. - Seamless backup

Unlike standby redundancy systems, there is no delay or wait time when switching from primary to standby unit. As a result, the system provides peace of mind for processes with fast responses and processes where safety is paramount. - Online maintenance

In addition to redundancy, all modules can be hot-swapped, allowing maintenance without interrupting plant operation. - Certified ISASecure

EDSA 2010.1 Level 1 certified.

Inquiries