The Control Valve 6000 Series , utilizing optimal design through CFD analysis, significantly enhance control performance while contributing to productivity improvements throughout the entire plant lifecycle. This includes reduced installation costs, space-saving design, and improved maintainability.

Features of the Control Valve 6000 Series

Control Valve 6000 Series

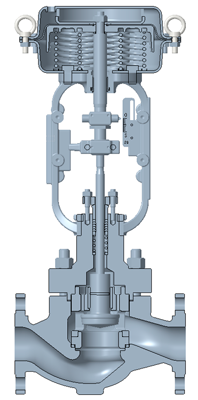

| Valve type | Single Seated Valves | Image

|

|---|---|---|

| Model No. | AS_11 | |

| Size | 1/2 in. to 4 in. | |

| Pressure rating | • JIS B2220-2012 JIS10K, 16K, 20K, 30K • JPI-7S-15-2011 Class 150, 300, 600 • ASME B16.5-2020 Class 150, 300, 600 • HG/T20592-2009 PN10, 16, 25, 40, 63, 100 • HG/T20615-2009 Class 150 (PN20), 300 (PN50), 600 (PN110) | |

| End connection | Flange: RF flange | |

| Body material | ASTM A216 WCB / JIS SCPH2 ASTM A351 CF8 / JIS SCS13A ASTM A351 CF8M / JIS SCS14A | |

| Trim material | ASTM A479 316 ASTM A479 316 + CoCr-A seat ASTM A479 316 + CoCr-A face | |

| Temperature range | -45 to + 400 °C | |

| Leakage performance | Classes IV, V | |

| Cv range | 0.1 to 245 | |

| Range ability | 15:1 to 100:1 | |

| Application | stabilizer structure | |

| Option | Low-emission gland packing system |

Improvement in Rated Cv Value

By adopting a stabilizer structure at the lower part of the valve body, we have achieved a 129% increase in the rated Cv value compared to model AGV.

High Rangeability

A wide rangeability of 100:1 enables superior control performance.

Optimal Structural Design

Through precise simulations of fluid behavior using CFD analysis*, we have implemented optimal structural design.

Utilization of Flow Test Facilities Compliant with International Standards

By utilizing flow test facilities compliant with international standards, owned by Azbil Kyoto Co., Ltd. (Location: Funai-gun, Kyoto Prefecture; President: Toshikazu Ishii), we have significantly improved reliability and efficiency through actual measurement evaluations. This also allows for the reduction of energy loss through appropriate valve selection.

*CFD Analysis: Computational Fluid Dynamics refers to the numerical simulation technology that models the flow of fluids (liquids and gases) on a computer.