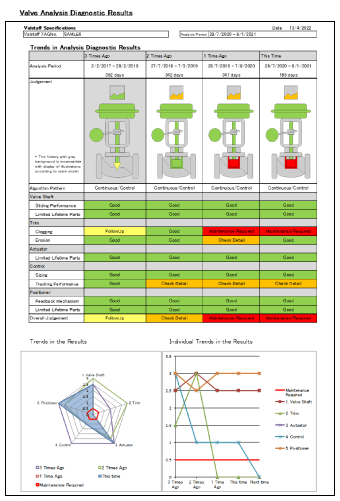

Primary screening diagnosis

Valves connected to the control valve maintenance support system PLUG-IN Valstaff are checked and those with abnormal data trends are identified.

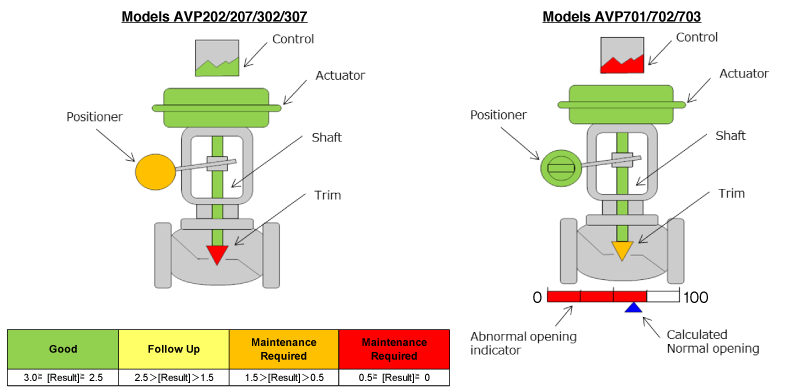

This makes it possible to identify valves that need attention from among the hundreds of valves at the plant and to determine their condition. The valves requiring attention are assessed in the 5 areas shown below, and a summary report is presented that contains overall assessments and radar charts.

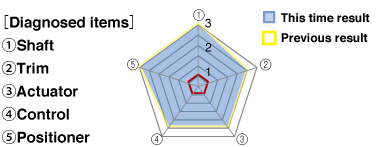

Radar charts

- Radar charts show the results of assessment for each diagnosed item.

- Valve health is rated on a scale of zero to three, with three being the best.

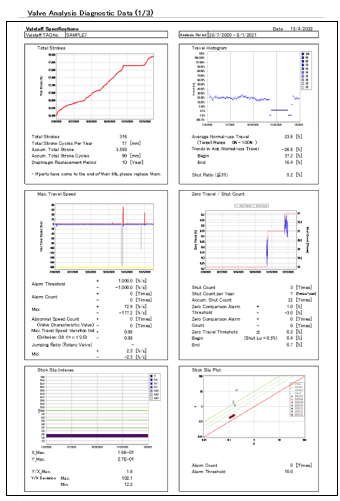

Detailed diagnosis

A thorough analysis of valves that were found to have strong abnormal trends during primary screening diagnosis, as well as customer-specified valves, in order to gain an in-depth understanding of their condition.

We submit a detailed diagnostic report, as described below, and as necessary we can meet with you to help with maintenance planning.

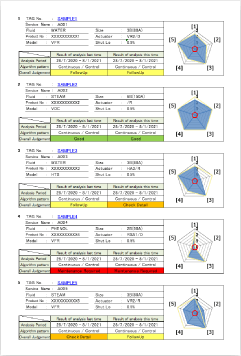

- Abnormality areas

- Abnormal opening range(only Models AVP701/702/703)

- Changes in an abnormal trend

- Abnormality assessment data

Detailed analysis report (sample)

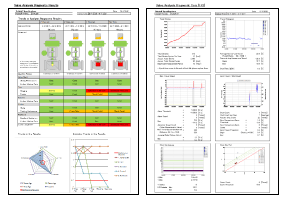

Comparative verification

Even valves with completely identical specifications have different characteristics depending on the fluid used and operating conditions. These characteristics can be understood by repeated comparisons of diagnoses with valve overhaul inspection results.

Comparative verification helps with accurate valve maintenance planning by providing diagnostic information tuned to the characteristics of individual valves, which is not possible with regular diagnosis.

Comparative verification

Diagnostic results

Overhaul inspection results

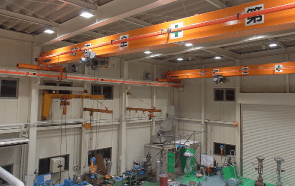

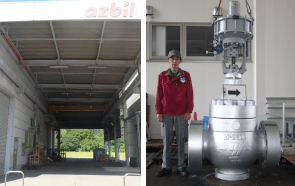

Azbil’s valve maintenance

We have established valve maintenance centers as bases for control valve maintenance, with specialist engineers to provide high-quality and high-value-added maintenance based on the latest equipment and the superior technology and know-how that we possess as a valve manufacturer.

Features of valve maintenance centers

- The centers are installed at five of our locations, Kawara Technology Center, Kashima, Chiba, Yokkaichi, and Mizushima, to provide valve maintenance services throughout Japan.

- We conduct high-quality inspection, maintenance, and repair of both our products and those of other companies.

- When work is concentrated in a particular area, we coordinate professional engineers, work places, and equipment to respond quickly.

- Using our positioners and diagnostic software, we provide diagnostic and analysis services for valves and suggest optimal maintenance plans.

- In order to provide the same services overseas as in Japan, we provide training to develop specialized engineers.

We provide control valve solutions that contribute to increased value in all situations at sites related to control valve control and management, from process automation (PA) to factory automation (FA) sites. By leveraging our strengths in providing integrated services from consulting through to engineering and maintenance, we provide step-by-step plans to boost the renovation and improvement of production sites.

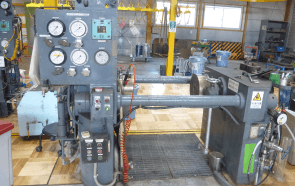

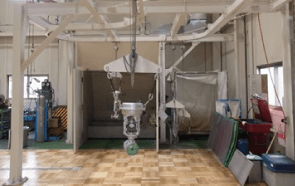

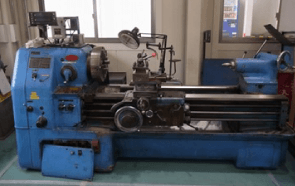

Equipment in valve maintenance centers

Inquiries