FAQs

A

The Valve Diagnostics Service provides assistance by diagnosing the deterioration of control valves using various calculation parameters sensed by Azbil Smart Valve Positioners attached to valves used at a wide range of manufacturing facilities (chemical plants, steel plants, etc.), power plants, and other kinds of facilities. The service provides early detection of valve abnormalities that could previously be found only in overhaul inspections, and it predicts abnormalities various parts of the valve. This helps prevent sudden problems and equipment shutdowns caused by control valve malfunction.

A

We make diagnoses based on analysis of the enormous volume of data collected and accumulated on a 24-7-365 basis by the control valve maintenance support system PLUG-IN Valstaff, as well as the wealth of expertise and experience we have cultivated throughout our eight decades as a control valve manufacturer. Various valve operation parameters are sensed and calculated in tens of milliseconds inside Azbil Smart Valve Positioners that are attached to control valves.

A

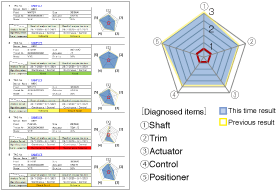

We find hunting, sticking, galling, damaged trim, clogged trim, problems with closing performance against fluid differential pressure, insufficient supply air pressure, and problems with the positioners’ air circuits.

A

We present you with reports that rate the controllability of diagnosed valves and deterioration in four valve areas, with an evaluation of each as Good, Follow up, Check thoroughly, or Maintenance required. We also provide consultation and advice regarding diagnoses upon request.

A

Generally no.

Note: In the case of manufacturer-specific special valves, there might be some difference.

A

In some cases. In the case of FOUNDATION Fieldbus (FF communication), our service only supports Yokogawa DCS CENTUM.

Note: Installation of the control valve maintenance support system PLUG-IN Valstaff is a prerequisite.

A

There are two types: annual contract and spot contract (only when a diagnosis is needed).

A

No.

Inquiries