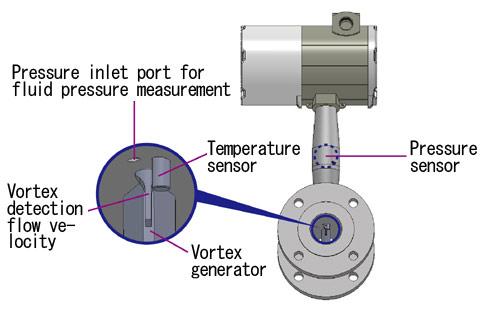

This inline multivariable vortex flowmeter can measure the volumetric or mass flow rate of liquids, gases, and steam. A built-in platinum resistance temperature detector and semiconductor pressure sensor enable measurement of mass flow rate that is compensated for temperature and pressure.

- The volumetric or mass flow rate of liquids, gases, and steam can be measured.

- Selectable outputs: flow rate, temperature, pressure, calculated density of a fluid

- Highly reliable structure with no moving parts.

- Wide temperature range, from cryogenic liquefied gases to high-temperature gases and superheated steam.

Model AX2_ _ _ Multivariable Vortex Flowmeters incorporate azbil Group proprietary technologies and are multivariable and insertable. They measure flow rates of various fluids including liquid, gas, and steam, over a wide range of temperatures from -200 to +400 °C. These multivariable vortex flowmeters make highly accurate measurements of the flow rate of gas and superheated steam in particular.

Multivariable functionality is achieved by three built-in sensing elements, a vortex shedding flow velocity sensor, a pressure sensor, and a temperature sensor. Because they measure flow rate, fluid temperature, and fluid pressure, these flowmeters can measure the mass flow rate of various fluids including gas, liquid, and steam, by means of density compensation. In addition, because they are insertion type, these flowmeters can be attached and detached without stopping the process, thereby lowering operating costs by reducing downtime.

Inline type, insertion type

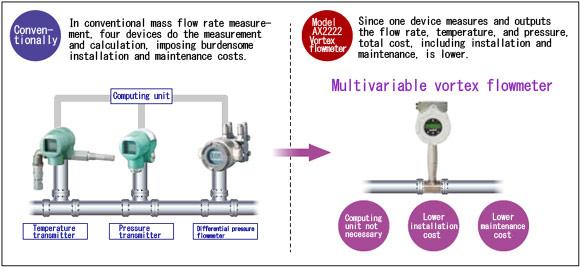

- For improved measurement efficiency and lower costs, this single unit provides the functions of four devices, flowmeter, pressure transmitter, temperature transmitter, and mass flow rate computing unit, and can output a selection of three items from among volumetric flow rate, mass flow rate, temperature, pressure, and calculated density.

- The density compensation function based on the measurement of temperature and pressure allows a highly accurate measurement of the mass flow rate.

A single unit fulfills 4 roles!

Density compensation for the fluid is done by measuring its temperature and pressure. This makes it possible to measure with high accuracy the mass flow rate of superheated steam or of a gas whose density changes depending on the temperature and pressure.

Since a single unit can measure and output flow rate, temperature, and pressure, in a process that measures these three variables it is not necessary to install and wire multiple devices, allowing a reduction of the overall cost.

Excellent density compensation function based on temperature and pressure

Here, the density calculation formula based on the Boyle-Charles method (the formula used for the density compensation of ordinary gas) and that employed by this flowmeter are compared.

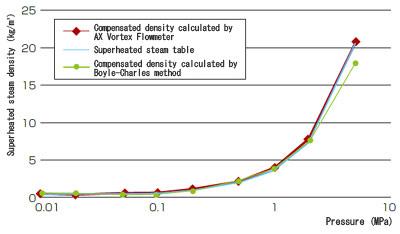

The density calculated by the Boyle-Charles method and the density calculated by the formula used by this flowmeter are compared by taking superheated steam at 320 °C as an example and assuming the value listed on the superheated steam table to be the true value. This shows that the density calculated by this flowmeter is a good match with the density in the superheated steam table.

As the pressure increases, the density calculated by the Boyle-Charles method increasingly deviates from the density in the superheated steam table (Figure A.)

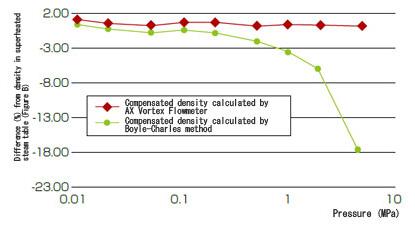

Figure B shows the error in densities calculated by this flowmeter and by the Boyle-Charles method relative to the density in the superheated steam table. This error contributes to the mass flow rate accuracy error.

This flowmeter can accurately measure the mass flow rate because it is does so based on a correct density calculation, and therefore it can measure the mass flow rates of various superheated steams and gases.

■ Density of superheated steam at 320 °C (Figure A)

■ Difference (%) from density in superheated steam table at 320 °C (Figure B)