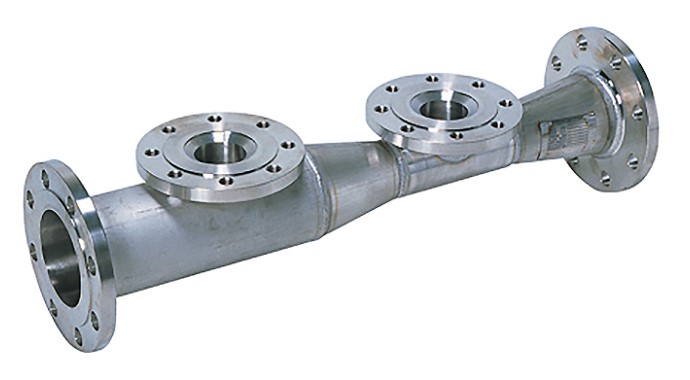

A venturi flowmeter without a connecting pipe (pressure tap)

- Because no connecting pipe is used for detecting the differential pressure, the flow rate of slurry, fluid containing suspended matter, and corrosive fluid can be measured.

- The cone-shaped smooth throat minimizes pressure loss.

- The flow rate of a liquid that solidifies or vaporizes when its temperature changes can be measured.

The Tapless Venturi Flowmeter is a Venturi flowmeter that does not have a pressure output port (tap). A remote seal type differential pressure transmitter is used instead of connection piping for differential pressure detection, so the flow rate of slurry, fluid containing suspended matter, and corrosive fluid can be measured with minimal pressure loss. The flow rate of liquid or gas that solidifies when its temperature drops, or liquid that vaporizes when its temperature rises, is also measurable.

Measurement of a wide range of fluids

This flowmeter can be used in various fluid applications including: adhesive fluid whose crystals precipitate on the diaphragm surface (latex, black liquor, enriched ammonium sulfate, various saturated liquids, etc.), fluid containing fiber (pulp liquid, etc.), strong corrosive liquid (copper sulfate electrolyte, benzyl chloride, various chemical liquids), coagulative fluid (highly viscous oil, naphthalene, dehydrated tar, fatty acid, sodium sulfite, etc.), two-phase flow (gas + liquid), and solid + liquid.

Low pressure loss

Since pressure loss is small compared to that of an orifice, there is less energy loss and consequently less power is needed.

Instrumentation without connecting pipe

Since this flowmeter utilizes a remote seal transmitter, no connecting pipe is needed, reducing pipe installation and maintenance costs.